Skylight and Rooflight Measurement & Installation Guide

Hassle-Free And Simple Fitting

The supplied skylight is easy for a builder to install.

Our skylights are able to be installed conveniently on insulated upstands when coupled with builder-provided building materials.

All information and diagrams relating to installation that you can see here is only for the purposes of general guidance since every project varies in construction and design depending on the drawings of the architect. Also, upstand design and dimensions can vary depending on the insulation specifications and architect’s drawings.

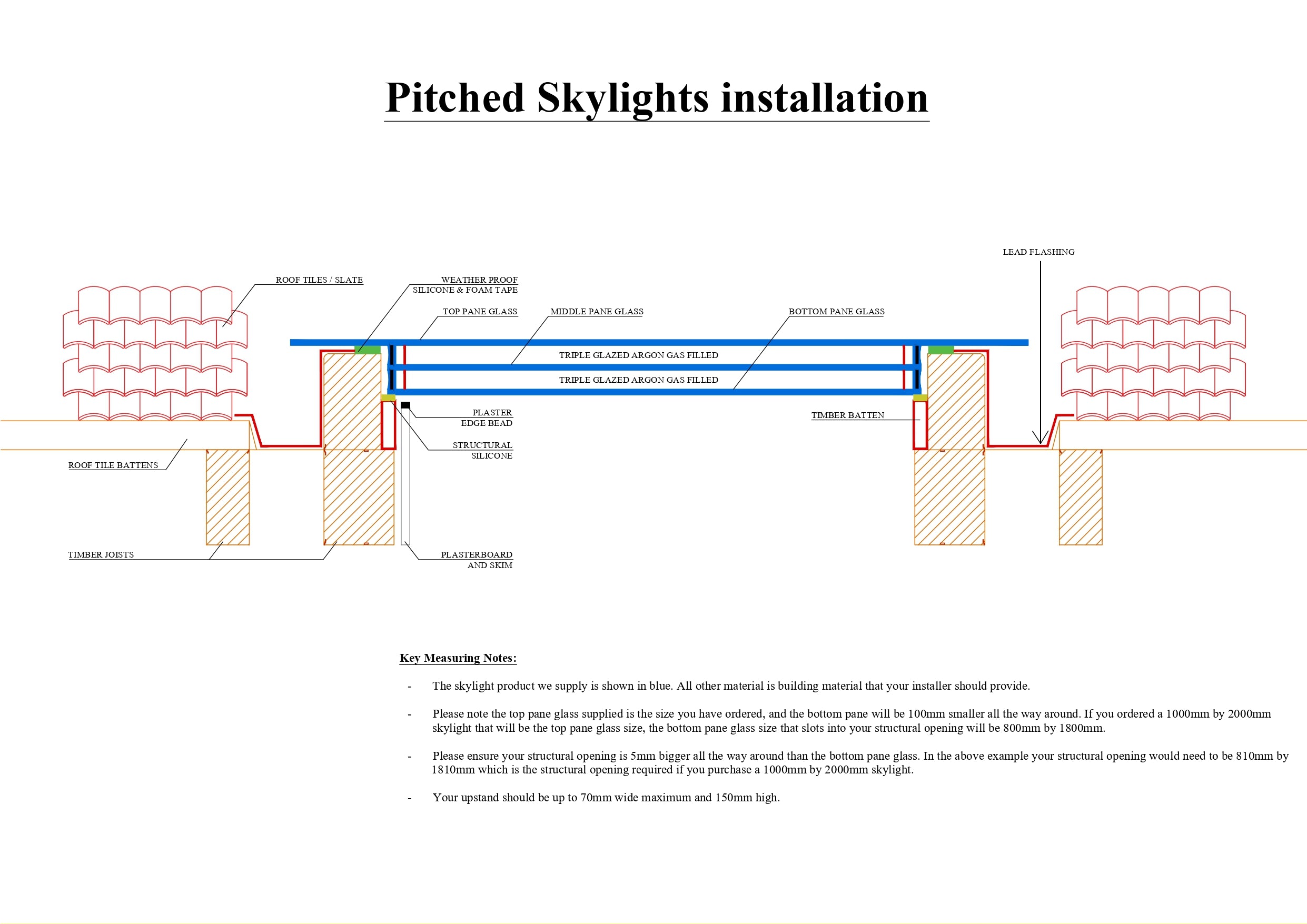

How Is The Opening Measured?

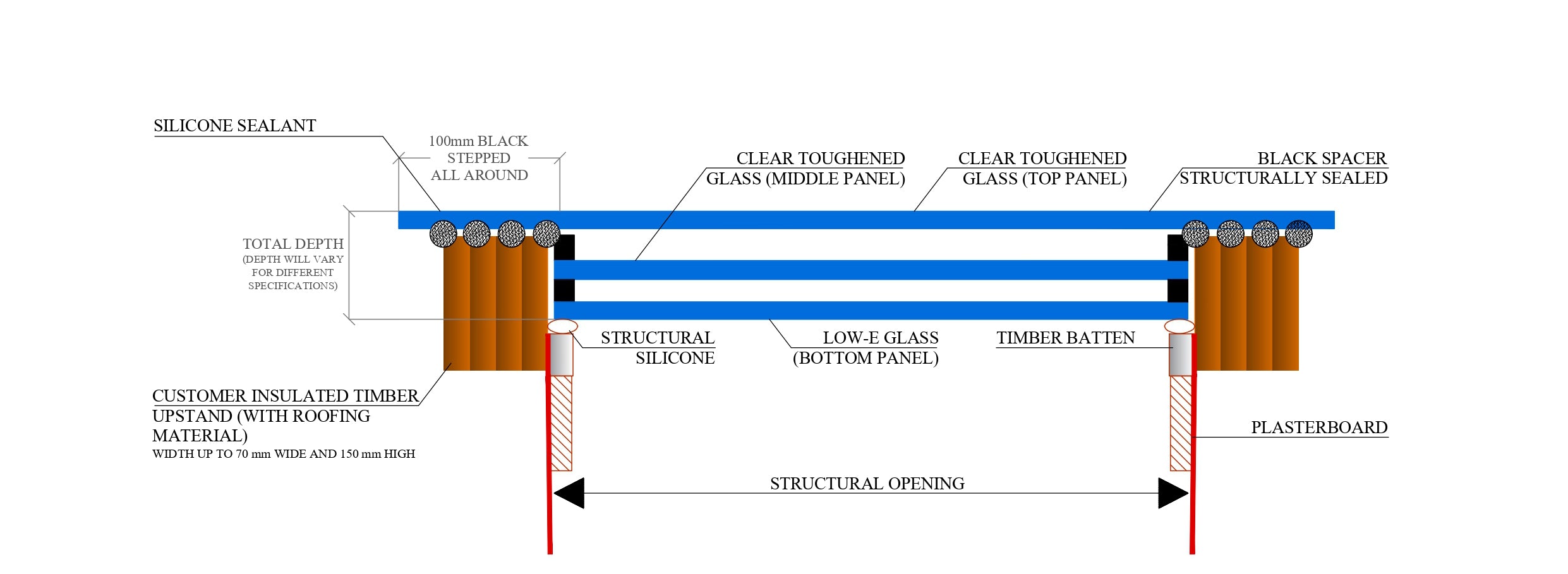

Before purchasing the skylight, you first need to measure the opening in which the skylight is going to be fitted. It’s vital to leave 5 mm tolerances around the entire structural opening so that the bottom pane of the skylight can effortlessly fit into the space. The opening is the hole in the roof.

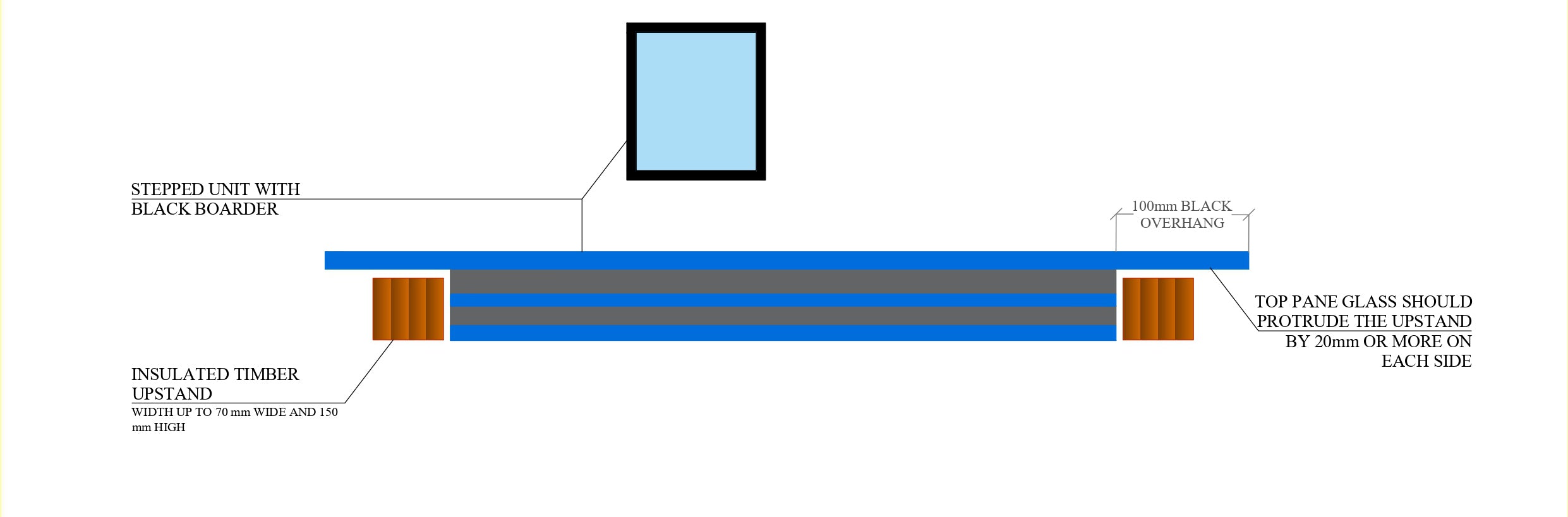

As an example, if you’ve bought skylights measuring 1000 mm x 1000 mm, this represents the dimensions of the glass’s top pane that will rest on the upstand’s top. The lower glass pane is 100 mm smaller around its sides, resulting in measurements of 800 mm x 800 mm. The structural opening, therefore, must be 810 mm x 810 mm, with the upstand width of a maximum of 70 mm and a maximum height of 150 mm.

A 100 mm black border and a step of 100 mm is all around the top glass pane.

Roof Preparation

The skylight will be secured to the timber upstand that is prepared by the builder or roofer during the process of constructing your flat roof.

It’s essential for your timber upstand to have a minimum protrusion of 150 mm above your roof. The pitch must be a minimum of 6°, as this is enough to enable the free flow of water downward so that water will not pool on the glass surface. The maximum pitch for the installation must be no more than 45°. For the easy clean solution to work optimally the pitch should be 10 degrees. The rooflight can be installed at lower pitches but this would mean the self-clean coating wouldn’t work as effectively and you may get water pooling on the top. We recommend pouring water over the top glass before bonding it if you want to install at a lower pitch.

Skylight Installation

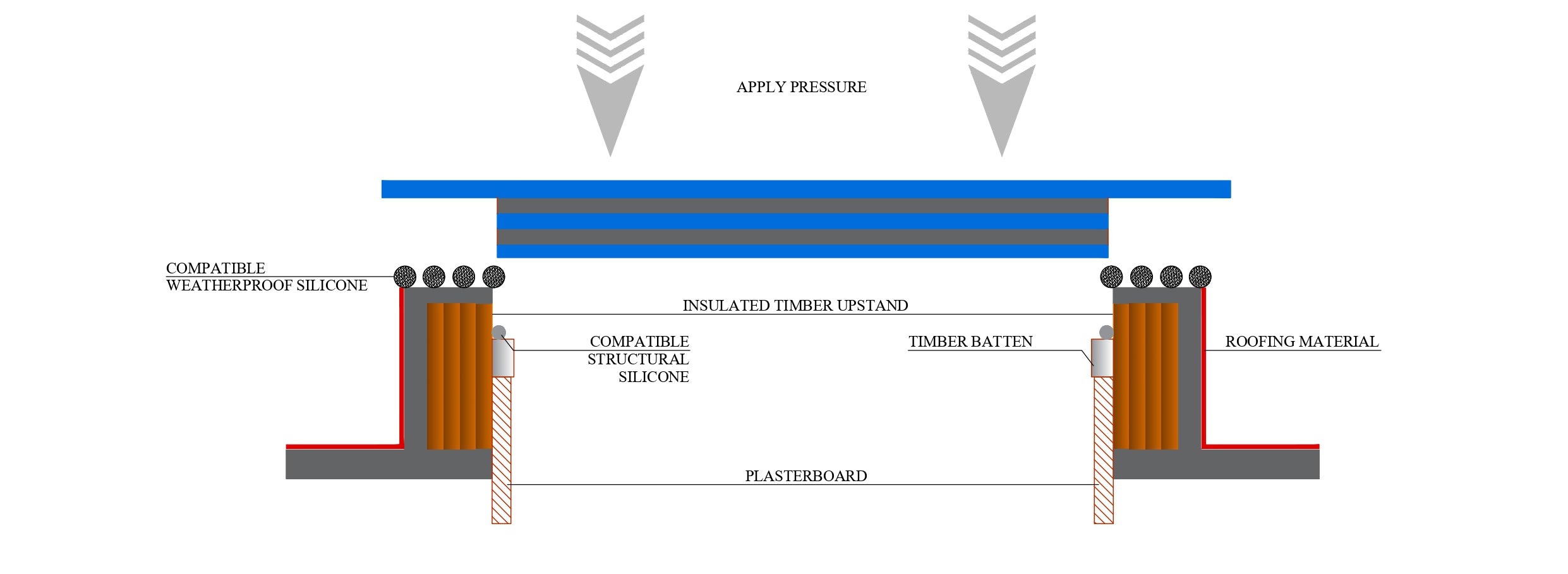

The final step that you need to complete when finishing your roof before installing the skylight involves the application of the roof covering onto the side of the upstand, thus making it weatherproof.

Before the product is sealed with silicone, you can apply water to it to test whether it can flow off effectively. Should pooling occur, you may need to raise the pitch. In order for optimal function of the easy-clean solution, the roof pitch must be at least 10 degrees with adequate wind flow to all directions.

Dowsil 791 silicone must be applied in reasonable amounts to the top part of the upstand as per the datasheet provided by the silicone supplier. After this, the top skylight pane can be placed onto the upstand’s top. Pressure should be applied around this top pane to enable even spreading of the silicone so any gaps will be effectively sealed.

All of the four bottom pane sides must then be supported once it has been put into position with the timber batten with top aluminium strip section at the top bonded and fitted before the plasterboard. A suitable structural silicone must be applied between the surfaces of the aluminium trim and the glass bottom pane as per the datasheet provided by the supplier, and it must be secured firmly in place. Excess silicone should be wiped away with finishing tools and the plasterboard may be installed at this time.

Only a sealant that is compatible with setting bocks, the aluminium angle trim, the glass, and the upstand’s top must be used. Dowsil 791 weather-proofing silicone or Dowsil 895 structural sealants are the best choices. Note that some sealants require the application of primer to surfaces first.